THESE ARE TESTING TINES FOR SURE!!!!!!!

Reliance Hexham are experienced in many industries, in particular, the fork tine industry. This area not only requires experience and knowledge, but facilities and tradesman with the skills to complete the work.

There are quite a few Australian Standards that encompass the safe use and repair of fork tines. Reliance Hexham have complied to these standards now for over 20 years repairing and modifying tines for our customers. In some cases Reliance Hexham have manufactured and imported fork tines.

One important fact when inspecting your tines to Australian Standards is that fork tines MUST have stamping on the side of the tines with the capacity in kilograms and at what distance from the shank.

For example, 5000 x 600 (as seen in the image below) means the pair of tines are good for 10T at 600mm from the front face of the shank.

The next point is to make sure the tines are not worn. Having the correct equipment, training and knowledge to check this is another important step in the assessment of whether tines can be re-certified.

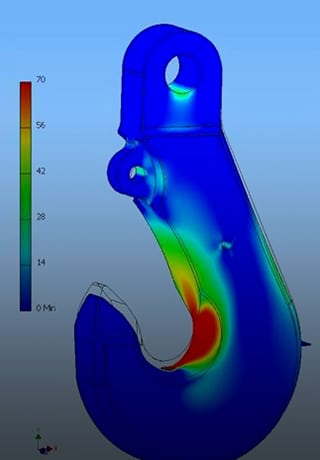

Now comes the most important step of all. Making sure there are no indications or cracks located in the tines. Cracks are repairable in tines. Below are extracts from AS4973 “Inspection and repair of fork arms in service on fork-lift trucks".

So if stress fractures are found in the heel of a tine (and this is quite common), honing the indications out but not taking the tine past its wear limit is acceptable. Typically, indications are also found in the eye and ITA hooks on tines. If the correct welding procedure, and pre and post weld procedures are followed, repairing these indications is also acceptable.

So if stress fractures are found in the heel of a tine (and this is quite common), honing the indications out but not taking the tine past its wear limit is acceptable. Typically, indications are also found in the eye and ITA hooks on tines. If the correct welding procedure, and pre and post weld procedures are followed, repairing these indications is also acceptable.

However if an eye or hook requires replacement, the fork tines must be proof loaded to the calculation given in the Australian Standard. This is another area that Reliance Hexham have extensive experience in.

Reliance Hexham is a National Australian Testing Authority (NATA) accredited testing laboratory for both magnetic particle testing and proof load testing. Repairing and re-certifying fork tines for our customers are a cost effective process opposed to replacing.

The final point that should always be considered is Inspection Intervals.

Below is an extract out of AS4973.

Reliance Hexham has many large customers that complete regular 12 monthly and some 6 monthly inspections. Prevention is always better than cure so finding early indications and removing these can extend the service life of tines.

Reliance Hexham are happy to help with your asset management. If you would like to discuss further, please contact sales@reliancehexham.com.au and we will help you manage your fleet.

If you need advice on your fork tines feel free to call and discuss or even try our live chat feature on our website www.reliancehexham.com.au

FIND US ON OUR SOCIAL PAGES BELOW