Welcome to our second Q&A segment! This month we are touching briefly on Australian Standards AS3637 "Winding suspension equipment". We have Darren Grant joining us, Reliance Hexham's Sales and Marketing Manager to answer your questions. To watch the full video follow the link below! If you would like to skip to a section in particular, there is a full breakdown of the questions asked below.

What are the important compliance requirements of AS 3637 for mine end users?

Firstly, I would like to mention that here at Reliance Hexham, we offer training packages for equipment relating to shaft equipment, what requirements you should know about AS 3637 and what inspections are required for shaft equipment especially your daily inspections. If you are interested in this, please contact Darren at darreng@reliancehexham.com.au.

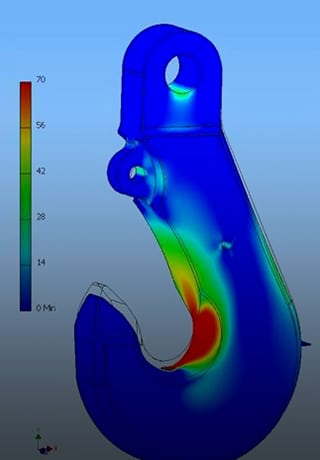

It is extremely important for engineering and maintenance personnel to learn and understand the compliance requirements set out in AS 3637. AS 3637 Type A material has a specific chemical composition and strict mechanical properties that must be adhered to. This Type A material is an excellent material for its specific application with specific alloying elements that give Type A superior ductility and elongation properties. This is very important especially when there is the risk of overwinds and equipment getting jammed. Due to this, Type A will elongate in these situations where as other materials would fail and potentially have catastrophic results.

Fatigue is another reason Type A material is used, especially considering the cyclic loading environment attachments are used in.The effects of cyclic loading on steel are not visually evident and difficult to quantify. Therefore, as part of Reliance Hexham’s due diligence, we ensure that during each recertification process we remove this from the equation by carrying out a stress relieving process.

Although we have barely touched the surface regarding AS 3637 staying on the subject of material I would like to mention on page 17 "C5.2 Heat treatment".

Heat Treatment shall be carried out within the following temperature ranges.

- Harden in oil or water between 870C & 910 C

- Temper between 55C & 660C”

This is a typical harden and temper process and the responsible mine personnel should ensure their attachments have the correct heat treatment process carried out with the required mechanical outcomes.

That concludes this months Q&A Segment. Thank you to everyone who sent in their questions!

Please keep those questions coming in to darreng@reliancehexham.com.au. You can also head to our website to use our “live chat” forum where we would be happy to answer your question immediately.

FIND US ON OUR SOCIAL PAGES BELOW