Reliance Hexham was recently commissioned to test and document the torque settings on rail carriages transporting logs. These were grown in the Walcha area and delivered to Timber Mills in the snowy region. This was due to the significant decrease in timber supply following the black summer bushfires.

As a NATA (National Association of Testing Authorities) registered testing laboratory, we are often sent enquiries seeking our help and experience in the field of testing, documentation and compliance to standards and regulations.

"How often have you really thought about whether a bolt you have tightened is tight enough or possibly even too tight?”

Every bolt has a recommended torque setting. Due to the large scale of these carriages, there would be significant consequences if the bolts were too loose or even too tight!

150 of these carriages held approximately 18T of logs each. A purpose-built bolster or rack to keep the logs stacked was attached to rail carriages. Each bolster had 12 bolts securing the bolster to each carriage. The bolts were rattled tight with a impact gun in preparation of loading.

The team at Reliance Hexham then undertook a torque setting and document inspection.

“Would you think the bolts were over tightened or not tight enough given that they were tightened using an impact gun?”

It was the latter! Our team found that nearly every bolt was not tightened to the recommended torque setting.

In the chance of a failure, it is important to have the support from a company such as Reliance Hexham that has completed thorough inspection of the torque setting when an investigation is completed. This is to provide evidence that the task of tightening bolts was completed correctly.

This isn’t the first time that the lashing or attaching of equipment that requires transporting has required our expertise.

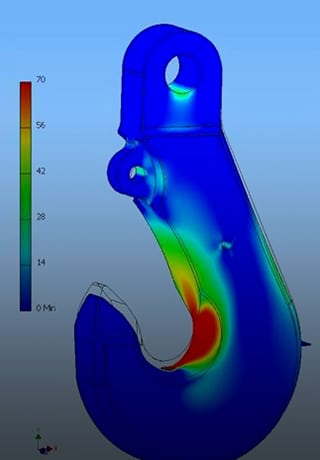

Another similar project we have undertaken was to calculate the breaking force of a lashing on a trailer carrying roadside lighting. Our team assessed whether the lashing points attached at different angles were adequate.

Once the forces were calculated the lashing points were tested to the requirements of “Load Constraint Guide 2018” published by the NHVR (National Heavy Vehicle Regulator) See below.

Next time you have a load to transport make sure it is LOCKED AND LOADED with the help of our team at Reliance Hexham.

FIND US ON OUR SOCIAL PAGES BELOW