Interested in knowing why forging is stronger, more durable, safer and more cost effective?

Forging involves a process of manufacturing steel quarters to create metal products by using a combination of heat and mechanical energy. As a result, this creates a higher level of structural integrity than any other metalworking process.

Forging offers consistencies in composition and structure of the design as it maintains granular flow, doesn't create structural voids and can often be the most cost effective form of metal manufacturing.

Comparing forged products to alternatives, forged products are significantly stronger and more durable. The durability is significant when looking at the difference between what happens when a forged product Vs alternative composed product undergoes a higher burden of weight than it has been designed for. Here, the forged product will bend and stretch (as a warning) before breaking, whereas alternative composed products will break without warning.

When is forging most suited?

- When there is a risk of the parts failing prematurely. As previously mentioned, forged products will showcase a warning prior to breaking completely.

- When an application requires high strength and durability.

- When stress and loads are constant

- Any demanding industrial lifting applications

The features of forging that make it stronger, durable and more cost effective.

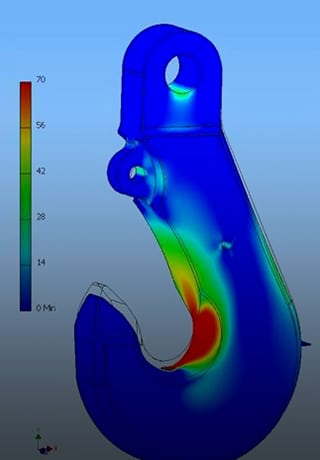

- Forging manipulates the steel to the desired shape creating strength by the grain flow contouring to the shape.

- Forging refines the grain to a homogeneous structure

- Forging can often be the cheapest option-because there is less waste from steel stocks.

A few facts about Forged products.

- Forged parts have a 26% higher tensile strength than other methods

- Forged parts have a 37% higher fatigue strength.

- Other products only have 66% of the yield strength of forged steel.

- Forged parts have a 58% reduction in area when pulled to failure.

Why Reliance Hexham?

- We have the facilities and the certified staff to match. Our strong team of qualified and highly experienced specialised blacksmiths have a combined total of over 100 years of experience with forging customised solutions and over 25 years individually.

- We are able to anticipate any challenges your product may face throughout its service.

- Reliance Hexham has all of your design and engineering solutions and will go the extra mile to develop the right solution for your individualised setup.

- We have a fully automated furnace, so supplying heat treatment graphs & forging heat temperatures are available & presented in a professional graph style display.

- We are Compliance and Quality assured and certified to Australian Standards.